[2002-01-18] Puzzle table

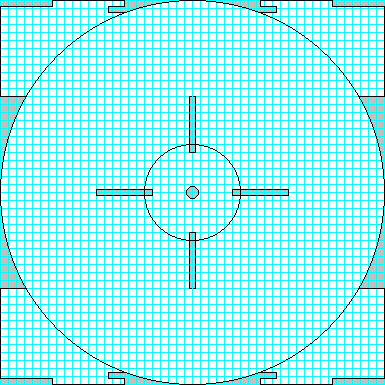

This is a low table for sitting on the floor in the Japanese fashion. It is made from six parts, all cut from the same piece of 4x4' finish-grade plywood in a manner intended to minimize wastage. The principle is simple: You cut a circle out of a square and make legs from the corners.

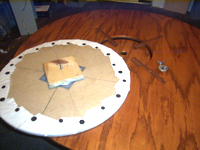

The pieces slot together stably without any adhesive or fasteners, making the table easily collapsible for storage or transportation.

This table is derived from my earlier puzzle chair in that it uses the principle of forming legs and surface with a single, circular cut in the proximate center of the parts blank. Because it was designed as a low table for floor seating, however, the leg-pieces would not be deep enough to accomodate the entire circumferance of the surface-piece, and so they had to be cut in four pieces, instead of two, and a means improvised whereby they might be joined together stably without the use of fasteners or adhesives and without obtruding above the finished surface of the table. Thus was the "dimple" in the center of the table introduced. It serves as a hub onto which the four leg pieces may slot in an elementary fashion. When accurately made, this subassembly is completely stable on its own, and when the upper surfaces of the leg-pieces are slotted into the table-top, it becomes rock-solid.

Four 2x2' floor cushions fit nicely into the table's quadrants. The hole in the middle of the table is intended to accomodate the cord of a lamp, or an accessory such as the lazy susan shown below.

It was intended that the table parts be cut out using a computer-controlled (CNC) router, but I have made two prototypes (which have been in service for 1 and 2 years, respectively) using only a drill, a reciprocating saw, and a router to finish the edges.

Note, finally, that if a more traditional end- or dining-table (i.e. one with a height equal to at least the radius of the surface) is desired, the 6-part "hub" assembly can be foregone in favor of a simple 3-part assembly which amounts basically to a puzzle chair without the back.

last modified 2002-01-18